Electric

Spindle

Spindle

Smart Technology

Successfully developed an eco-friendly and digitalized smart CNC

Electrically

driven clamping system.

Eco-friendly Smart CNC Lathe

Applied to Hyundai Wia KIT-4500 and on sale

Equipment equipped with electric spindle system

Equipment equipped with electric spindle system

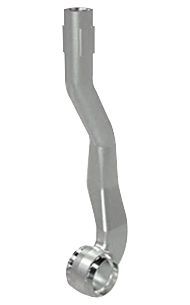

Aluminum special alloy chuck

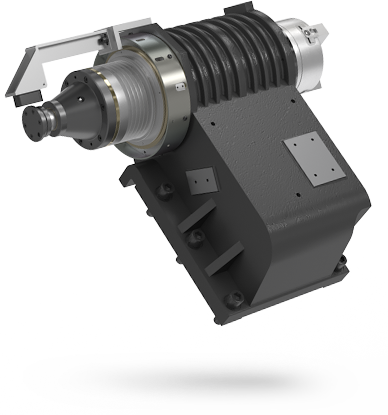

Electric spindle system

Electric spindle system

Smart machine tool that can be compacted and eco-friendly and ICT convergence is possible by removing the hydraulic system

Precise control by electric force enables precise adjustment of clamping force

Application of energy-free mechanical mechanism as a clamping locking device during rotary machining

Energy-saving electric spindle system with integrated clamping system and rotating system

Precise control by electric force enables precise adjustment of clamping force

Application of energy-free mechanical mechanism as a clamping locking device during rotary machining

Energy-saving electric spindle system with integrated clamping system and rotating system

Eco-friendly

Digitalization

Smart CNC.

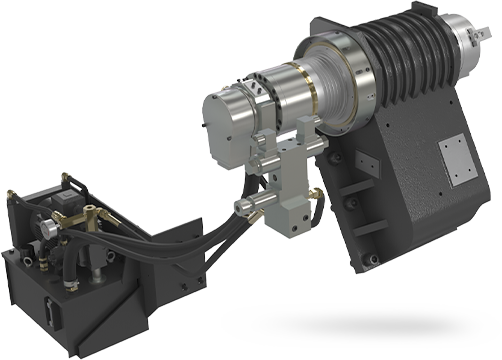

Hydraulic

Spindle System.

Spindle System.

Conventional hydraulic spindle system

Complex structures with hydraulic systems

Hydraulic pulsation (hydraulic cylinder vibration)

Oil leakage, vibration and noise

Hydraulic pulsation (hydraulic cylinder vibration)

Oil leakage, vibration and noise

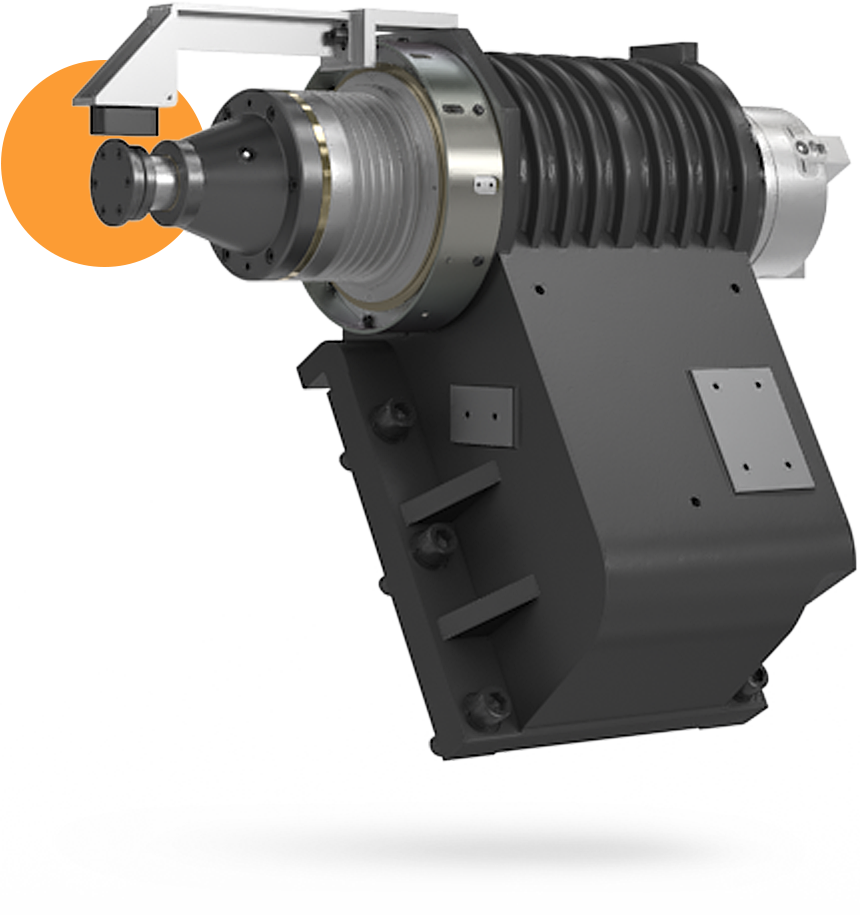

After

Electric

Spindle System.

Khanstn Electric Spindle System

Elimination of hydraulic system, simplification of structure

More than 3 times improved surface finish compared to hydraulic pressure

Eco-friendly and digitalized smart CNC

More than 3 times improved surface finish compared to hydraulic pressure

Eco-friendly and digitalized smart CNC

Saving Energy,

Saving Money.

90%

Reduced power consumption

40%

Reduced maintenance cost

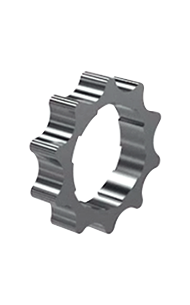

Aluminum

Alloy Chuck

Exceeding the limits of existing steel axes.

Developed the world's first aluminum chuck

40% weight reduction

55% reduction in vibration of the main spindle

3 times improvement in surface roughness

More than 25% tool life extension

Increase productivity, reduce energy consumption

High product

completion.

completion.

Hard-to-cut material

High-quality, precise production of difficult materials as well as easily deformable materials

BEARING

GEAR

ROTOR

SOCKET

PULLEY