Large Horizontal Rotary Table

(Large Size Table)

Suitable for horizontal machining centers or boring machines

Equipped with special wear-resistant bronze/nickel alloy double lead worm wheel

and hardened steel worm shaft to ensure high precision and long-term division precision

Can be produced according to customer's design and workpiece holding interface

High rigidity brake structure for hydraulic clamping and heavy cutting

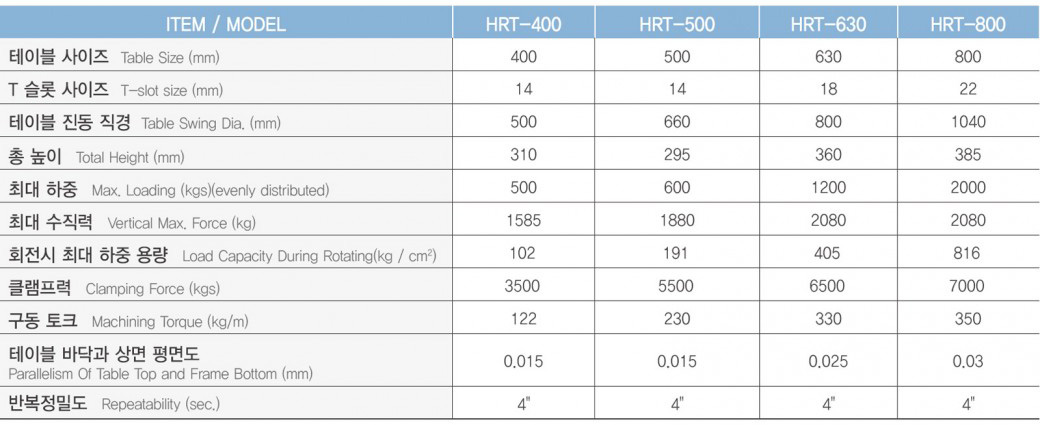

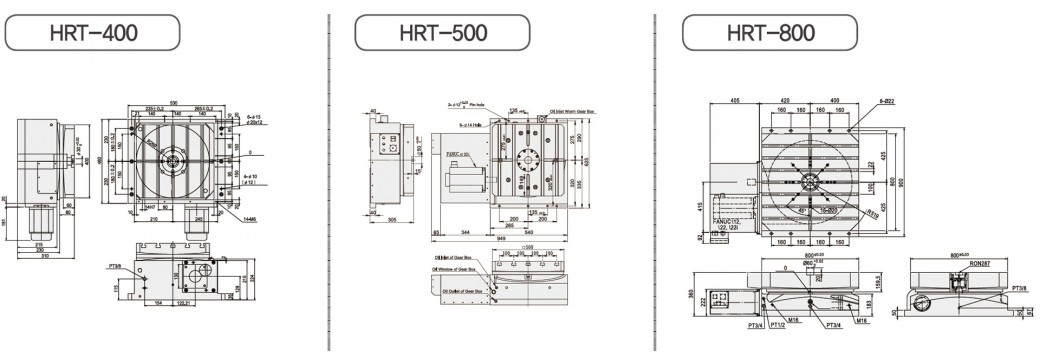

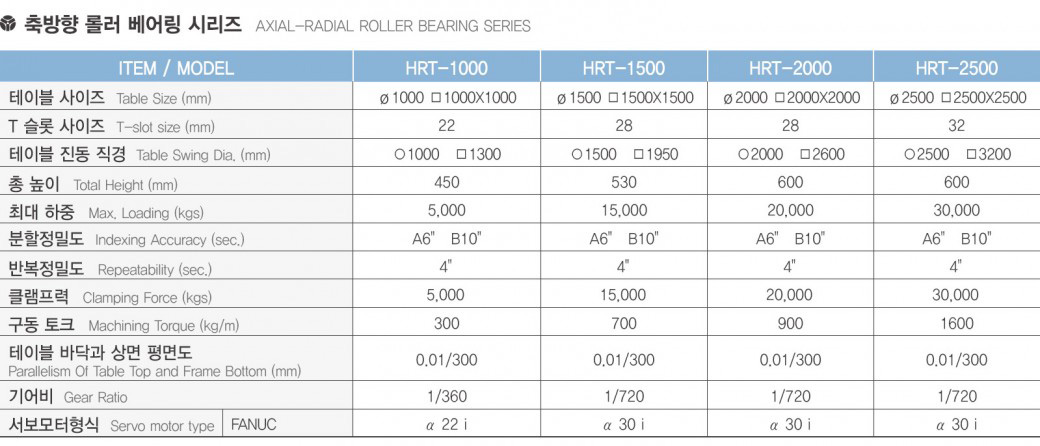

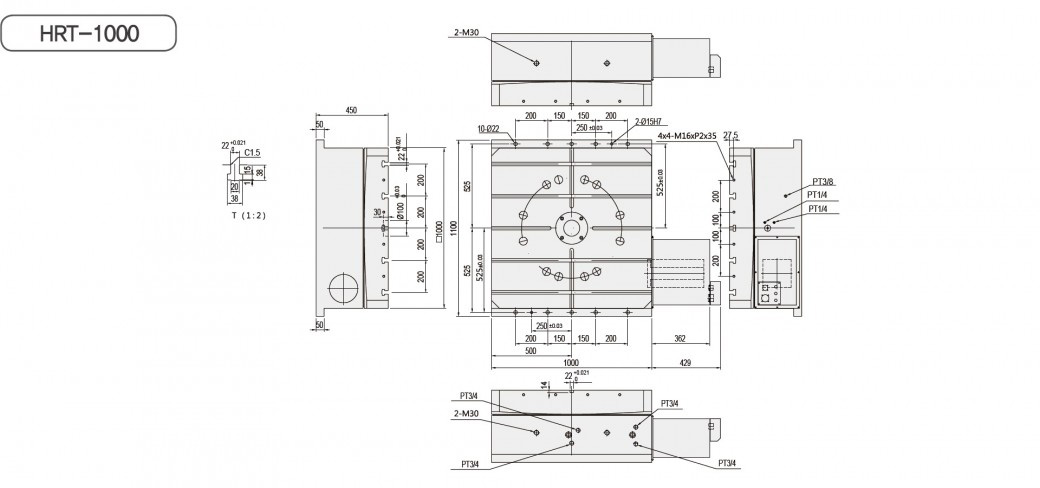

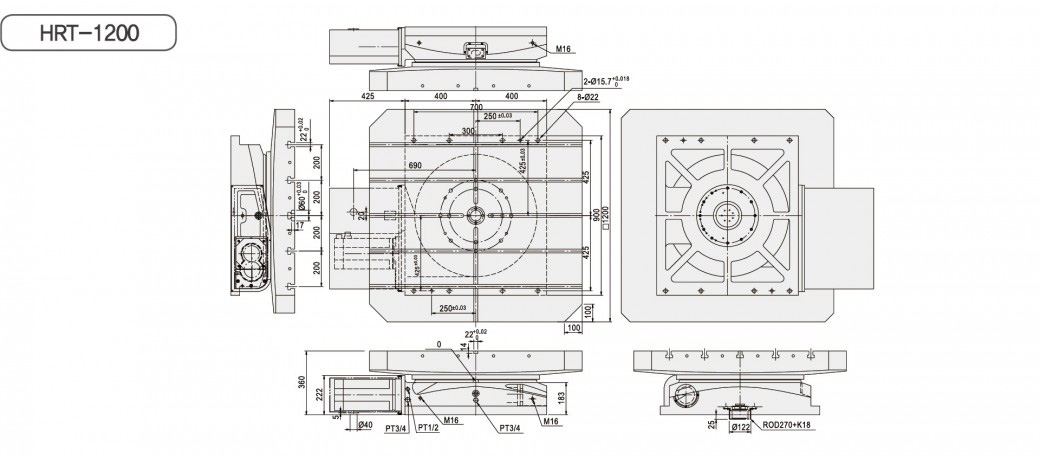

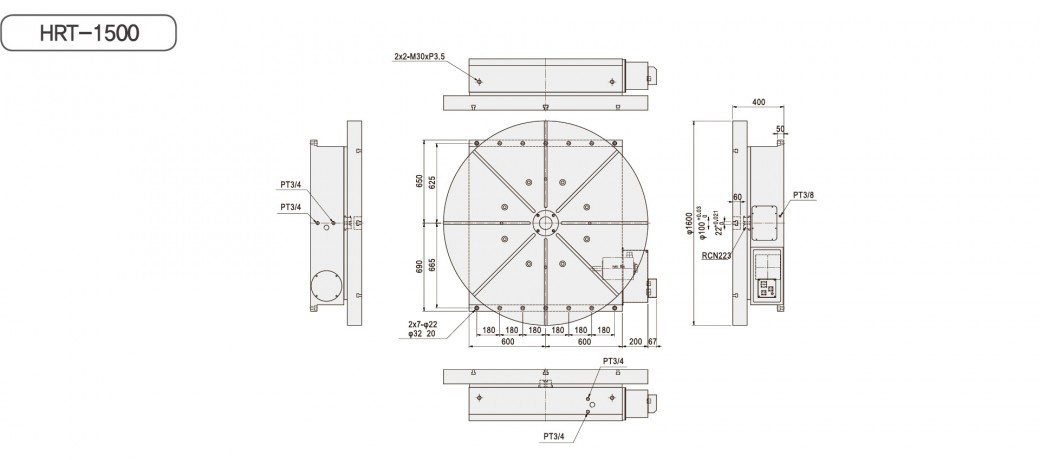

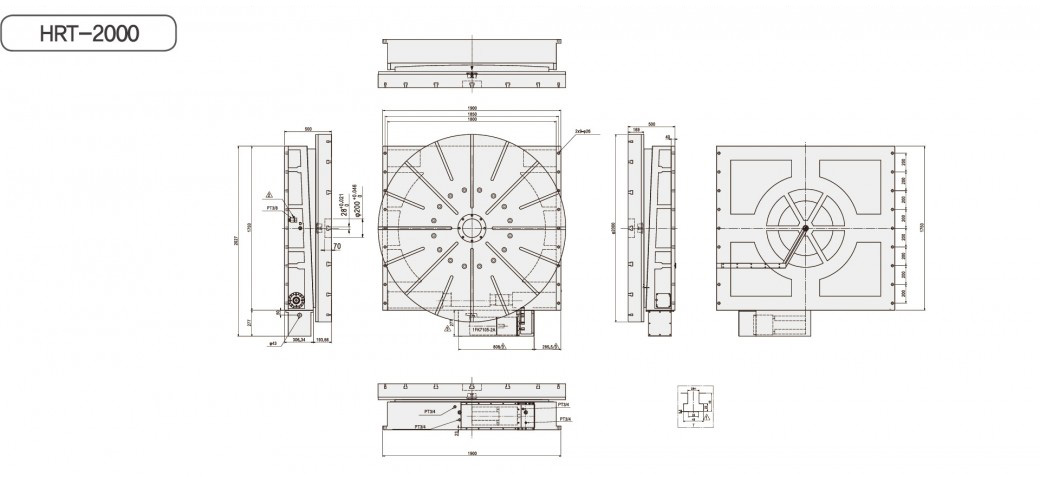

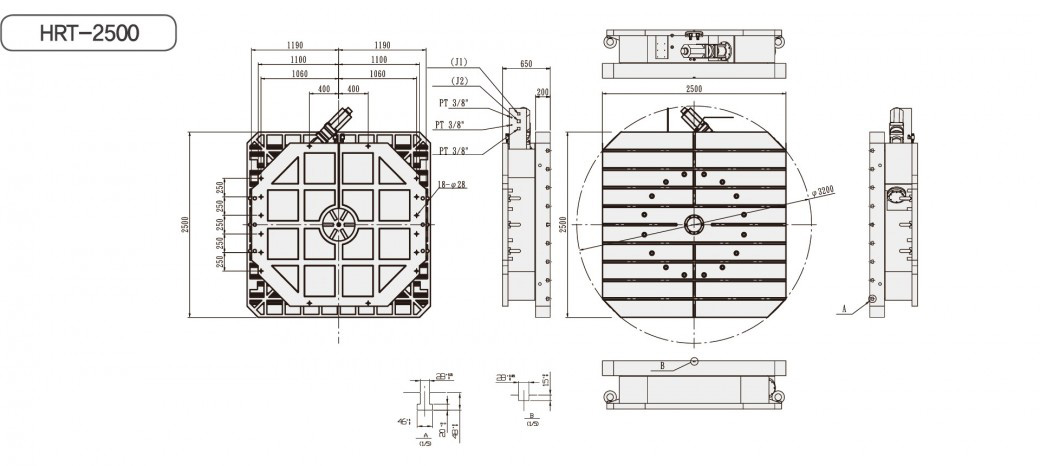

Table size from 400mm to 2,500mm

High-load, high-precision designs suitable for heavy-duty cutting

and measurement applications are also available upon customer request

Built-in hydraulic port system suitable for horizontal machining centers and special machines in the automobile/motorcycle industry

All components of the table are produced with high quality materials and techniques

All tables are subjected to a minimum of 48 hours of operation and precision testing

All electrical accessories are imported from Japan/Germany of reliable performance

The division precision when 0.001 degree is arbitrarily manipulated can be 6 seconds,

10 seconds, or higher division precision according to the customer's request.

Equipped with special wear-resistant bronze/nickel alloy double lead worm wheel

and hardened steel worm shaft to ensure high precision and long-term division precision

Can be produced according to customer's design and workpiece holding interface

High rigidity brake structure for hydraulic clamping and heavy cutting

Table size from 400mm to 2,500mm

High-load, high-precision designs suitable for heavy-duty cutting

and measurement applications are also available upon customer request

Built-in hydraulic port system suitable for horizontal machining centers and special machines in the automobile/motorcycle industry

All components of the table are produced with high quality materials and techniques

All tables are subjected to a minimum of 48 hours of operation and precision testing

All electrical accessories are imported from Japan/Germany of reliable performance

The division precision when 0.001 degree is arbitrarily manipulated can be 6 seconds,

10 seconds, or higher division precision according to the customer's request.